MCHEN MACHINE PARTS Co., Ltd Has several years experience in producing stainless steel/carbon steel/alloy steel products/rubber products. We have always adhered to the business policy of "Quality for Survival, Product for Development, Credibility for Cooperation and Service for Customers". We are pleased to find new partners and hope to establish longterm business relationships with you based on mutual benefits.

Our products have been exported to many countries and regions in Europe, North America, South America, Middle East and Asia.

MCHEN MACHINE PARTS Core Advantages

Abundant Production Experience

Years of professional manufacturing experience in metal and rubber machine parts production.

Strict Quality-Oriented Policy

Adhere to the business philosophy of quality for survival and credibility for cooperation.

Diverse Material Selection

Camlocks available in stainless steel, aluminum, brass, polypropylene, nylon and other materials.

Standardized Product Manufacturing

Products like hose fittings comply with EN14420 and DIN 2817 international standards.

Complete Product Range

Specialize in camlocks, hose fittings with safety clamps and various machine parts.

Excellent Product Performance

Camlocks feature tight seal, simple structure and easy operation for practical use.

Global Export Business

Products exported to Europe, North America, South America, Middle East, Asia and other regions.

Win-Win Cooperation Concept

Aim to establish long-term and stable business relationships based on mutual benefits.

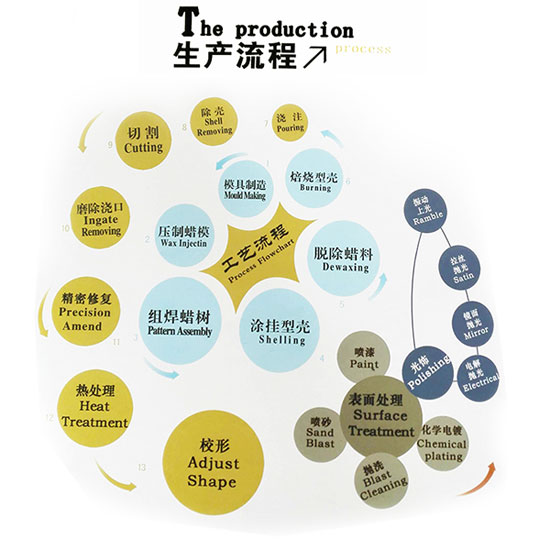

Production Process

| 1.Cutting | 2.Shell Removing | 3.Pouring | 4.Burning |

| 5.Mold Making | 6.Wax Injection | 7.Ingate Removing | 8.Pattern Assembly |

| 9.Shelling | 10.Dewaxing | 11.Amend | 12.Heat Treatment |

| 13.Adjust Shape | 14.Sand Blast | 15.Surface Treatment | 16.Final Finishing |

This infographic visually illustrates the intricate production process of investment casting, laid out in a circular, easy-to-follow flow. It breaks the process into color-coded stages, starting with wax injection and mold making, moving through shelling, dewaxing, and burnout, and progressing to finishing steps like polishing, plating, and shape adjustment. The design uses a mix of yellow, blue, and gray bubbles to categorize different steps, creating a clear visual guide to how a precision metal component is crafted from start to finish.

One-stop Mechanical Parts Solutions

MCHEN offers one-stop manufacturing, processing and sales services for a full range of mechanical parts including stainless steel quick couplings, pipe fittings, valves, flanges, marine hardware and rigging. With ISO 9001:2000 certification, we produce products in strict accordance with API, ANSI, BS, DIN, JIS and other international standards, supporting customization with diverse stainless steel and carbon construction steel materials. Our professional services cover multiple industries such as sea carriage, petrochemical, pharmaceutical, food and power vessel, and we provide reliable product supply for customers at home and in over 30 overseas countries and regions.

Professional Manufacturing

Professional Manufacturing

Standard & custom production of stainless steel fittings, marine hardware & mechanical parts

Precision Processing

Precision Processing

Professional parts processing, compliant with international standards

One-stop Sales

One-stop Sales

Integrated sales, supporting bulk & custom orders

Standardized Production & QA

Standardized Production & QA

ISO 9001 certified, made to API/ANSI/BS/DIN/JIS

Multi-material Customization

Multi-material Customization

Custom production with stainless steel & carbon steel

Industry-specific Solutions

Industry-specific Solutions

Tailored solutions for marine, petrochemical, food & power industries

Global Delivery & After-sales

Global Delivery & After-sales

Global delivery (30+ regions) with professional after-sales support

Factory & workshop Display